INNOVATION DEFINES THE FUTURE...

PRODUCTS GUIDE

Four Piston Actuator

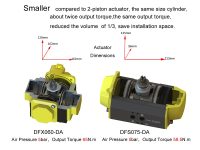

Smaller, Faster, Stronger

4x4 pneumatic actuator,exquisite appearance, compact structure.

A little use of space is sometimes valuable for site installation.

WHY 4X4 ?

Connection under the bottom confirms to standard ISO5211 and DIN3337, extra group holes were for ANSI or other standard valves connection via a transition plate made by our company.

Lots of double sauqured adaptors with different sizes that confirm to all the ISO5211 recommended valve stem dimensions,shaft with deep hole,direct installation was realized. Cost for valve assembly was saved.

Spring

Spring is nested between the piston and the end cap cut out recess, which ensures precise direction of travel.

4 chambers,there are many different spring combinations for it.To prevent winding,medium and small 3 sizes

springs forward and reverse rotation group each other is easy for maintenance.

High Strength Piston

piston made of higher mechanical strength,

more durable quality selection of high-strength

steel AISI1045, after 7 main procedure completed,

the surface 0.03mm chrome, enhanced wear resistance

and corrosion resistance.

O-RING

Piston&shaft fluorine rubber seals improve

the service life,stroke shortened compared to

conventional cylinder,seal life extends almost doubled.

Two Kinds Of End Caps

convex cap&flat cap,both caps are available double acting type,single acting mounting convex cap. End cap was made of high strength aluminum die-casting, deburring, grinding, polishing, anodized hardening, epoxy coating add up to 6 main procedure,500+ hours salt spray test.

According to different temp. environment,there are wearing repair kits supply,easy to replace.

Shaft Bearings

made of the material having a low coefficient of friction, in order to avoid metal to metal contact,

and easy for the replacement and maintenance.

Top mounting confirms to VDI/VDE3845,easy installation for positioner or limit switch boxes and other accessories.

DFX SERIES 4X4 PNEUMATIC ACTUATOR

Bottom interface confirms to ISO 5211/DIN 3337,easy connecting with industry valves.

Via 8 steps processing,aluminum rough die-casting - drill shaft hole - CNC turning - CNC Milling - Drilling&Tapping - Deburring - Anodized hardening - epoxy powder coating. Fixture design and manufacture all finished by ourselves.Same as our 2-piston actuator, the body was treated with double coatings(anodize hardening+epoxy powder coating), cylinder internal surface roughness Ra0.4-0.6, 25+μm oxide film makes the friction be minimized, thereby greatly extend the service life of the actuator, 150μm epoxy coating thickness and surface hardness above HV400 to ensure its wear resistance and corrosion resistance.

AL Die Casting Anodized Hardening Anticorrosive Primer Epoxy-polyester Coating

In short, one 4X4 pneumatic actuator,after completion of the various components of a continuous processing, but also need strict assembly and test,such a complex structure,the corresponding technical craft is also complex and difficult.

Cap comes with NAMUR standard air port, it can be installed directly with NAMUR solenoid valve.The drive pinion can beseperately adjustale at start/end point in the range of ±5°rotation,thus ensuring precise positioning of all of the fluid control applications, which means it can be adjusted between 85°and 95°.

Cylinder and piston surface were anodized (over 25μm thickness), and has a thickness of 200-250μm epoxy polyester coating. Therefore, our actuators can resist salt spray over 1000 hours.Besides certain solvents,epoxy coating is also very good resistance to acids and bases,and also good ultraviolet-proof.

In order to ensure the performance of these products, pls do not damage the coating.

*Based on different conditions, please refer to our <ALL TORQUE D-T COATING SPECS> should you have any special requirements for protective coatings,we shall try our best to meet you.

Quality comes from testing and inspection one by one step.

surface hardness of the

anodized hardening cylinder

salt spray test

Actuator creep test under high temp.

test roughness inside the cylinder treated by anodized hardening.

sealing performance test

output torque dynamic testing

test epoxy-polyester powder coating adhesive force

Actuator creep test under low temp.

output torque static testing

Certificates from third party

ABOUT US

CUSTOMIZATION

HELP CENTER

NEWS

CONTACT US

CopyRight 2016 © ZHEJIANG DINGFENG FLUID AUTOCONTROL EQUIPMENT CO.,LTD. All Rights Reserved. 23rd floor, Oushang Bldg, Louqiao Sub-district, Ouhai District, Wenzhou, Zhejiang, China